Laser etching is a process where a high heat laser beam is used to melt the surface of the target material the melted material expands and causes a slightly raised mark that reveals the desired image.

Laser etching granite process.

To increase the etching speed you can use systems with higher laser powers.

The process is much more efficient because there is no need to create a template and the laser beam is the universal tool for all shapes and material thicknesses.

Though all colors can be laser etched for these materials the choices and are better for granite.

The more homogeneous and fine grained the stone is the better the stone engraving results will be.

While laser engraving removes as much as two one hundredths of an inch of material from the surface of the material to create a discernible cavity laser etching melts just the first thousandth.

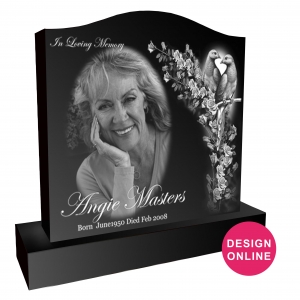

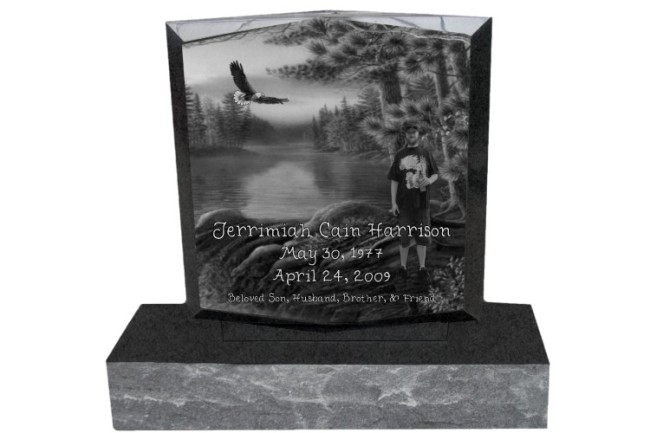

Marble used to be the most popular stone for graves but today it is granite by far.

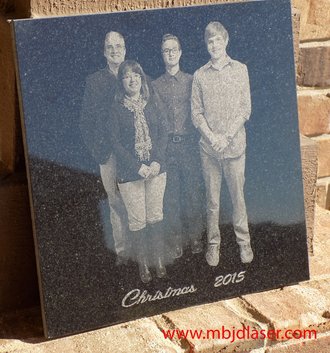

Granite the world s third strongest material has a matchless beauty and when paired with our laser etching technology a simple photo is transformed into a work of art.

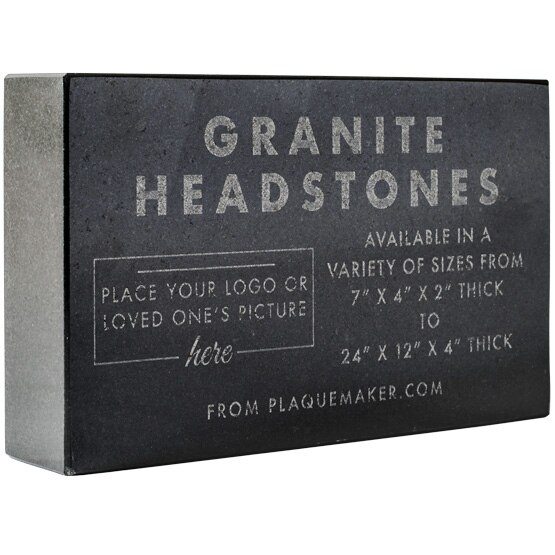

Toll free 800 533 3031.

The darker colors are better for laser etching with dark black granite being the best.

For more information on what we can do for you please call us at.

Our skilled photo editors enhance your image to the specifications needed for laser etching.

Laser etching involves manipulating an image photograph or other and having that image engraved directly onto black granite with a laser machine.

The customized laser etching process begins when we receive your favorite picture.

The result is both photo realistic and highly detailed.

It is important to note that the quality of the etched image greatly depends on the quality of the image we receive.

For most marking applications the maximum laser power you will need is 100w.

Laser engraving on stone is particularly effective with dark polished natural stones like granite marble and basalt.

The picture is then sent to the laser where it is engraved into granite using a laser beam 3 thousands of an.

The surface of the stone is melted during laser engraving so the material is processed directly.

Applications for stone engraving.

There are a few reasons for this.

Laser engraving as it applies to etching on stone is a process of removing the polished surface with a co2 laser and permanently etching into the natural exposed material depending on the images parameters.